We have a huge inventory, including horizontal flow wrappers and vertical machine types. Please contact us to discuss your options and get expert advice on the best shrink wrapping equipment and materials.

Flow Wrap Machinery

At Kempner, we offer a wide range of innovative flow wrap machinery that can used for a variety of different products, including:

- Household items

- Stationary

- Food

All flowwrappers in our flow wrapping machinery range are available with photocells for printed film registration. They can also come with a printer for dates, batch codes, etc. Please contact us to discuss your requirements and we can help to determine the most suitable flow wrapping machinery for your production needs.

Get in touch

with Kempner now

AHP – 400 Flow Wrapper Machine

Features include:

- Colour touch screen control panel

- Up to 100 packs per minute

- Reel width – up to 400mm

- Maximum pack height 100mm

- Maximum pack length 550mm

- Minimum pack length 40mm

- (though not all maximum dimensions can be applied together)

- Pack width up to 220mm

- External film reel diameter 350mm

- Air supply: 6 bar

- Electrical supply: 400V 50Hz + neutral + earth

- Power consumption 2.5Kw

- Machine weight 600 kgs

- Can be supplied as left or right-hand machine.

- All parts are built with ease of maintenance and cleaning in mind.

- Safety guarding

AHP – 500 Flow Wrapper Machine

Features include:

- Welded and stainless steel frame

- Colour touch screen control panel

- Up to 200 packs per minute

- Reel width – up to 500mm

- Maximum pack height 120mm

- Maximum pack length 620mm

- Minimum pack length 250mm

- (though not all maximum dimensions can be applied together)

- Pack width up to 220mm

- External film reel diameter 350mm

- Air supply: 6 bar

- Electrical supply: 400V 50Hz + neutral + earth 3 ph

- Power consumption 3.2Kw

- Machine weight 700 kgs

- Can be supplied as left or right-hand machine.

- All parts are built with ease of maintenance and cleaning in mind.

- Safety guarding

Swing 600 – Innovation and Simplicity

Features include:

- Cantilevered design for easy maintenance and cleaning.

- Colour touch screen control panel

- Speed 20 – 30 packs per minute

- Reel width – up to 600mm

- Maximum pack height 140mm

- Maximum pack length 1000mm

- Minimum pack length 50mm

- (though not all maximum dimensions can be applied together)

- Pack width 50 – 280mm

- External film reel diameter 300mm

- Electrical supply: 230V 50Hz 1 phase + earth

- Power consumption 2.0Kw

- Machine weight 300 kgs

- All parts are built with ease of maintenance and cleaning in mind.

- Safety guarding

What is a Flow Wrapper?

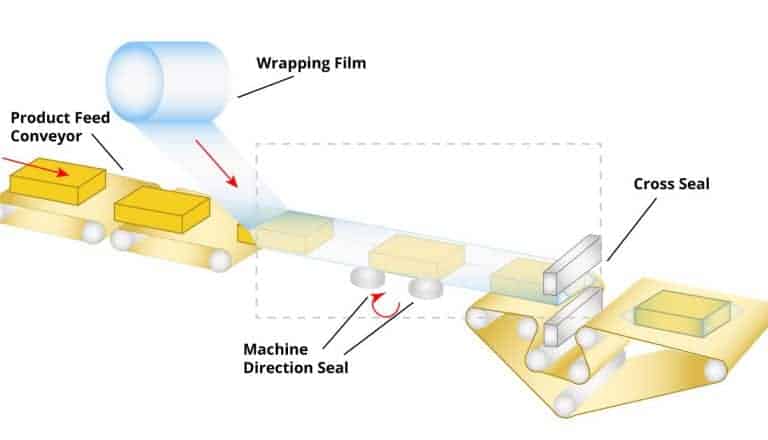

Flow wrap machinery is designed to package products by enveloping them in a flexible material, commonly a plastic film. Flow wrap machines, sometimes referred to as flow wrappers, are widely used in sectors such as food, pharmaceuticals, and consumer goods.

Flow wrappers can be customised to meet specific requirements, such as speed, size, and wrapping material. The machines are capable of packaging a diverse range of product shapes and sizes. Modern variants frequently include advanced features like touch screen controls, programmable settings, and the capacity to integrate with other industrial automation systems.

Flow wrapping is a technique that allows products to be sealed using a single continuous roll of film in conjunction with flow wrapping machinery. Products are conveyed along a horizontal line and flow wrap is heat sealed at either end.

Flow wrapping is also often referred to as FFS (Form Fill Seal), as well as pillow-pouch wrapping, fin-seal wrapping, or crimp-seal wrapping. Our flow wrap systems have been designed with quality, durability, production performance and economy in mind. Our models can also be interfaced with a variety of automatic feeding systems.

What Are The Benefits Of Using Flow Wrapping Machines?

Our flow wrapping machinery is available in both automatic and semi-automatic formats, so that you can find the right flow wrap machine to meet your packaging requirements.

By using flow wrapping machinery, you can customise the packaging to help increase branding. Clear flow wrap films enable your customers to view your products without any obstructions, increasing visibility and retail sales.

Flow wrap machinery offers a high production speed. This equipment is a perfect solution for enhancing the speed that your products are wrapped and ready to be sold.

Our flow wrapping equipment is very flexible, and it is possible to change to different pack sizes with ease due to the fact that the integrated conveyor systems are easily adjustable. This versatile machinery is ideal if you have a variety of different products with unique shapes and sizes which need to be wrapped.

What Materials Can Be Used With Flow Wrapping Machinery?

Flow wrapping machines are designed for use with OPP films, Polyethylene, and Polyolefin, with appropriate sealing head modification. These are durable materials that keep products fresh and protected. Products that have been flow wrapped also benefit from protection from outside contamination, whether that is from moisture, harmful UV rays or dust. They are also protected from direct handling.

Examples Of Flow Wrapping

You can find many instances of flow wrapping in packaging, from leaflets, to scratch cards and computer hardware to bread and cakes.

Flow wrapping machinery is beneficial for a range of different industries and at Kempner, we have leading equipment to ensure that you can increase production, get ahead of competitors and enhance revenue.

Flow Wrapping Machines Specifications and Features

Flow Wrapping Machinery FAQ

What types of products can be packaged using flow wrap machinery?

Flowwrap machinery is exceptionally versatile. It is capable of handling a range of different products, including food and non-food items. In the food industry, flow wrap machines are frequently used for packaging items such as chocolates, sweets, biscuits and baked goods. In the non-food sector, these machines can wrap anything from medical supplies, small hardware components, personal care products.

What are the speed capabilities of flow wrap machinery?

The operational speed of flow wrap machinery can substantially vary based on the specific model, as well as the size and shape of the products being packaged. Generally, these machines are designed for high-speed operation, and many models can efficiently wrap several thousand units per hour. This high-speed packaging capability makes flow wrap machinery an excellent choice for industries and businesses with high-volume production lines.

How much space will a flow wrap machine require in my facility?

The space requirement for a flow wrap machine is primarily dependent on the specific model you choose. Industrial-grade machines designed for high-volume production usually require more room, while smaller, compact models might fit comfortably in smaller facilities. Before investing in a flow wrap machine, it’s crucial to check the machine dimensions and compare them with the available space in your facility to ensure a suitable fit.

What are the energy requirements for flow wrap machinery?

The energy requirements for flow wrap machinery can differ based on the machine’s size, type, and operational features. While some compact models might run on a standard power supply, larger, industrial-grade machines might require a three-phase power supply for operation. Always verify the power specifications provided by the manufacturer to ensure your facility can meet the machine’s energy demands.

Can flow wrap machinery be integrated with my existing production line?

Many flow wrap machines are designed with integration in mind and can be smoothly incorporated into existing production lines. However, the level of integration can depend on various factors, including your current setup, the flow wrap machine model, and the nature of your products. Manufacturers or suppliers often offer expert consultation to help customise the integration process according to your specific requirements.

What's the lifespan of a flow wrap machine?

Flow wrap machines are robust pieces of machinery, and with regular maintenance, they can have a long operational life. The specific lifespan can vary significantly based on factors such as the machine’s build quality, the intensity of use, and the level of maintenance it receives. High-quality machines that are well-maintained and used appropriately can often provide reliable service for many years, making them a valuable long-term investment for businesses.

Is training provided for operating the flow wrap machine?

Yes, we can help our customers get to grips with flow wrap machinery. We provide training for optimal machine operation as part of the installation process. This training typically covers all aspects of operation, from basic controls to troubleshooting common issues, which can be invaluable in helping get the most out of the machine.

Modern flow wrap machines are typically designed with user-friendly control panels for easy operation. Regular maintenance for these machines usually involves routine cleaning, as well as checking the sealing components and conveyor belts for any signs of wear and tear. Periodic maintenance helps ensure optimal machine performance and longevity. Manufacturers often provide detailed operating and maintenance manuals and may offer technical support services as well.

How does flow wrapping improve efficiency?

Flow wrap machines are designed to significantly boost packaging efficiency in several ways. Firstly, their high-speed operation allows for the packaging of thousands of products per hour, far outpacing manual packaging methods. This can lead to considerable labor cost savings and increased production throughput. Secondly, flow wrap machines deliver consistent, high-quality packaging, reducing waste and enhancing the overall look of the product, which can be an essential factor in consumer appeal. Lastly, by providing a secure seal, flow wrap machines can help extend the shelf life of food items and protect non-food items from damage or contamination, adding further value to your operation.

Get in touch

with Kempner now

Contact us to discuss your options and get expert advice on the best

shrink wrapping equipment and materials.