Shrink wrapping is a vital part of many businesses. It is an easy and straightforward way to keep a large number of products together and make them easier to transport. But did you know that shrink wrapping can add value to your product? Below we cover three ways businesses have used shrink wrap for positive effect.

Water Bottles – Designing for Attractiveness

Bottles containing liquid by their nature are difficult to shrink wrap. They are very unstable and have an odd shape, meaning they can easily fall over inside a shrink wrap machine. Furthermore, when you pack six or 24 together at once, the shape becomes even more unstable.

Some people might treat this as a significant roadblock with shrinkwrapping the product. Where a pessimist sees the difficulty, however, an optimist sees the opportunity. Partnering with CHILLI, a brand agency specialising in packaging, Harrogate instead of using clear packaging like most of their competitors in the bottled water market, created a daring design using full-colour printing to negate the need for labels and find a new branding opportunity for their product.

Many companies are now using shrink wrap machinery to create high definition printed films on their products. In addition to brand awareness, using print also negates the need to design around shrink wrapping when designing the shape and label of your product.

Cucumbers – Designing for Longevity

In 2012 a book was published titled ‘Why Shrink-Wrap a Cucumber?’ about environmental packaging. The question of the title was not rhetorical: as we have covered before, shrink wrapping is essential for preventing oxygen from reaching the product contained inside the film, which in turn reduces the rate of decomposition and increases the shelf life of any perishables that are enclosed within.

As the book discusses in detail, a wrapped cucumber lasts three times longer than an unwrapped one. It retains its taste and texture: exposed cucumbers lose more than twice its weight after three days, while when shrink-wrapped it loses only 1.5% after 14.

Cucumbers are just one example of how vital shrink wrapping is for our supermarket produce. Cooked meats often come shrink-wrapped or in vacuum skinboard (VSB) format to reduce food’s contact with the atmosphere and extend its shelf life. In addition, the meat can be shrink-wrapped onto plastic trays to last longer than gas-flushed modified-atmosphere packaging alternatives.

In extreme cases where companies want to extend the shelf life of a product to its absolute maximum, high-end shrink wrapping machinery can use inert gases or heat treatment. This further delays decay and can prolong the shelf life of perishables and reduce the need to mark down prices of expired goods and minimize food waste in a way that no other form of packaging can manage.

Initially, plastic-wrapped products were a luxury precisely because it extended the life of food and drastically reduced food wastage. As old Cellophane ads highlighted, plastic wrap was essential in keeping produce healthy for long periods of time. As a result, greengrocers could sell food that stayed fresher for longer, and consumers could get access to a broader range of stock. To this day, good shrinkwrap packaging adds a large amount of value to perishable goods.

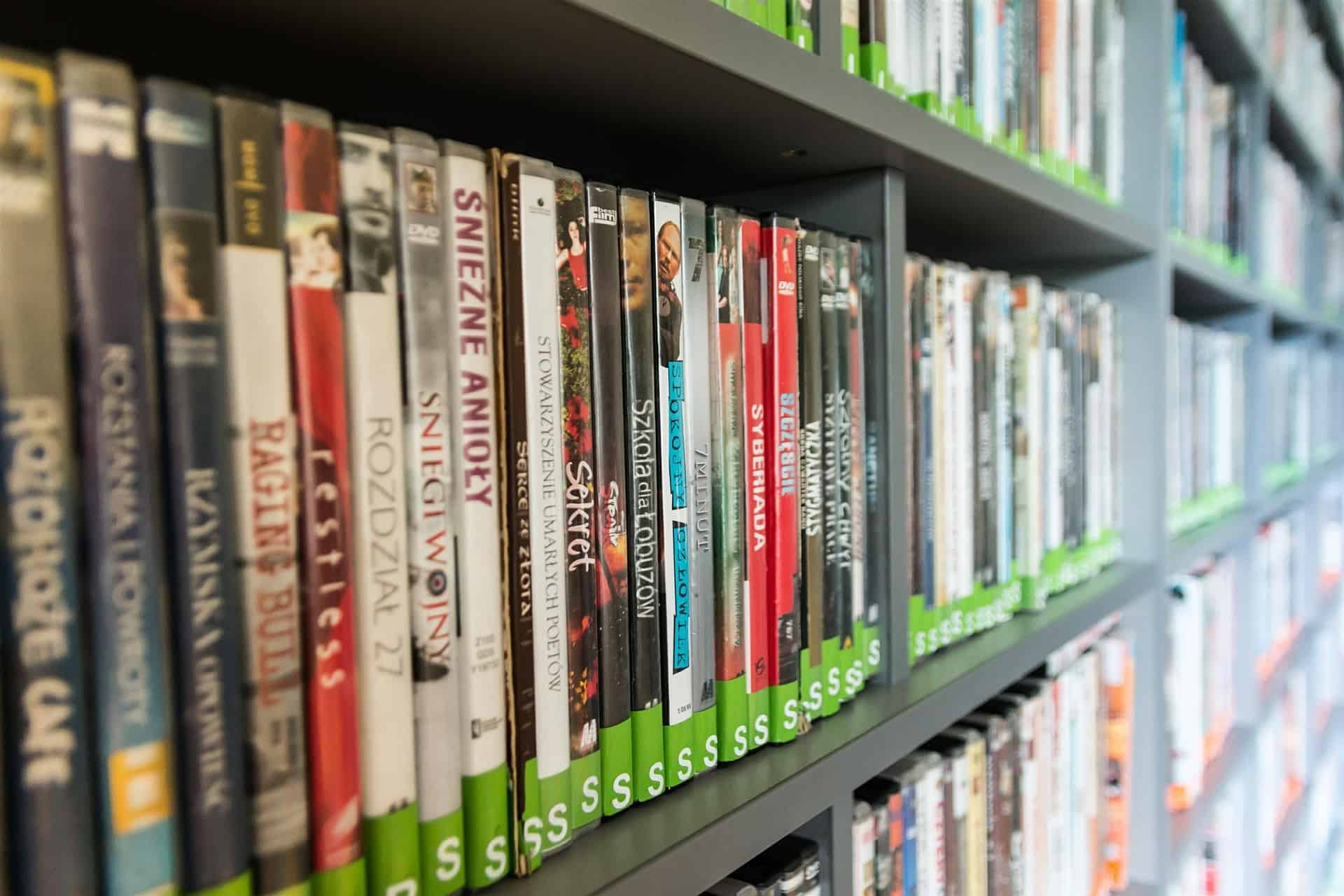

DVDs – Designing for Security

Retailers and manufacturers have since the dawn of time used packaging for physical protection. Soft fruit and vegetables get easily bruised and damaged, so plastic punnets or particular kinds of polyolefin shrink film like Ultra JD have been used to protect these products and make sure they look visually appealing.

Perhaps the most iconic example of shrink wrapping for security, however, are DVDs. One of the problems with selling these products without film is that it is easy to simply open up the case, take the disc, and leave the case behind with nobody being the wiser. Companies which do not wrap their DVD boxes in film invariably keep the discs behind the till and creates a cumbersome process at the checkout of finding each DVD, checking it is the right disc, putting it carefully in the box, and moving on to the next one.

By covering each case in a tight, light transparent film, you can safely leave the DVD inside of the box. It is immediately apparent at checkout whether the product has been tampered with, and it becomes much more cumbersome for a prospective thief to cut open the film without drawing attention to themselves.

The film also keeps the product looking new even after handling from consumers, and the transparent film lets you use the box for promotional graphics. Now almost every DVD, CD, and video game manufacturer uses shrink film over their products because of the unparalleled security features these thin, cheap pieces of plastic give.

In short, shrink wrapping machinery has many uses besides just containing your product. If you think you might need shrink wrap machinery, please contact us and leave an enquiry and we will be happy to provide you with our expert advice.