Many people get confused over the differences between shrink wrap packaging and vacuum wrap packaging, due to the look of the final product. Both methods use clear, flexible packaging materials that mould to the product. After this process, the look of both methods appears air tight, although we should note that shrink wrap does not produce a true vacuum within a wrapped pack, unlike vacuum wrap which purposefully removes all air.

Below, we have looked at the main distinctions between the two, to help clarify matters further:

What is shrink wrapping?

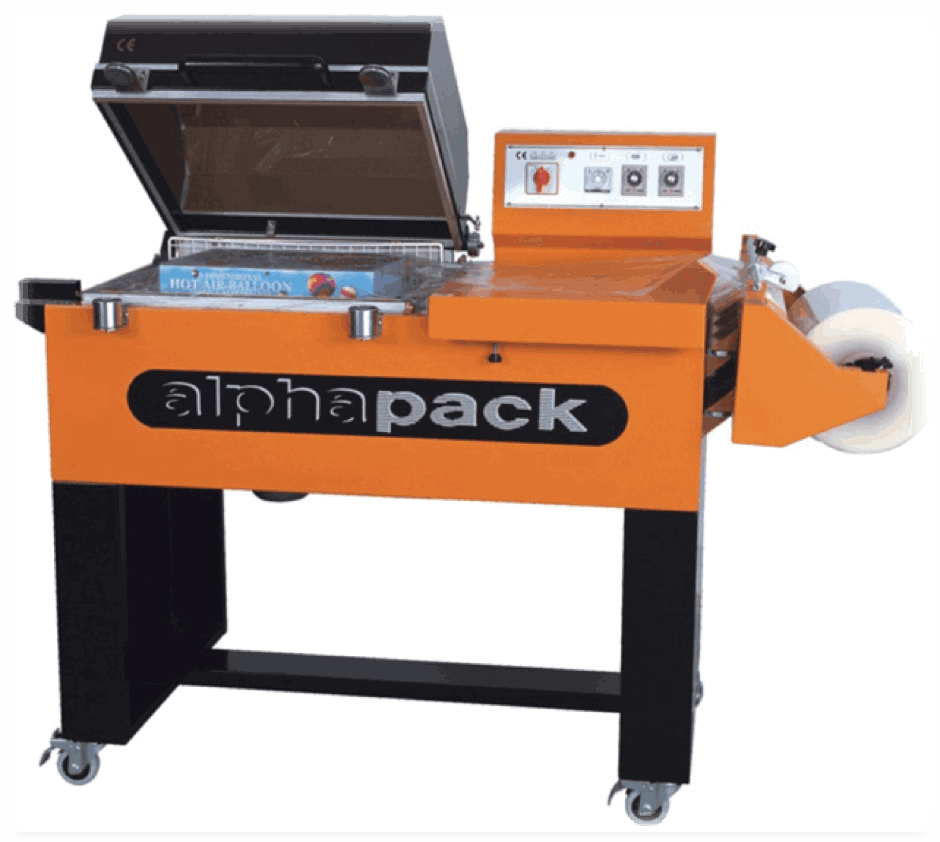

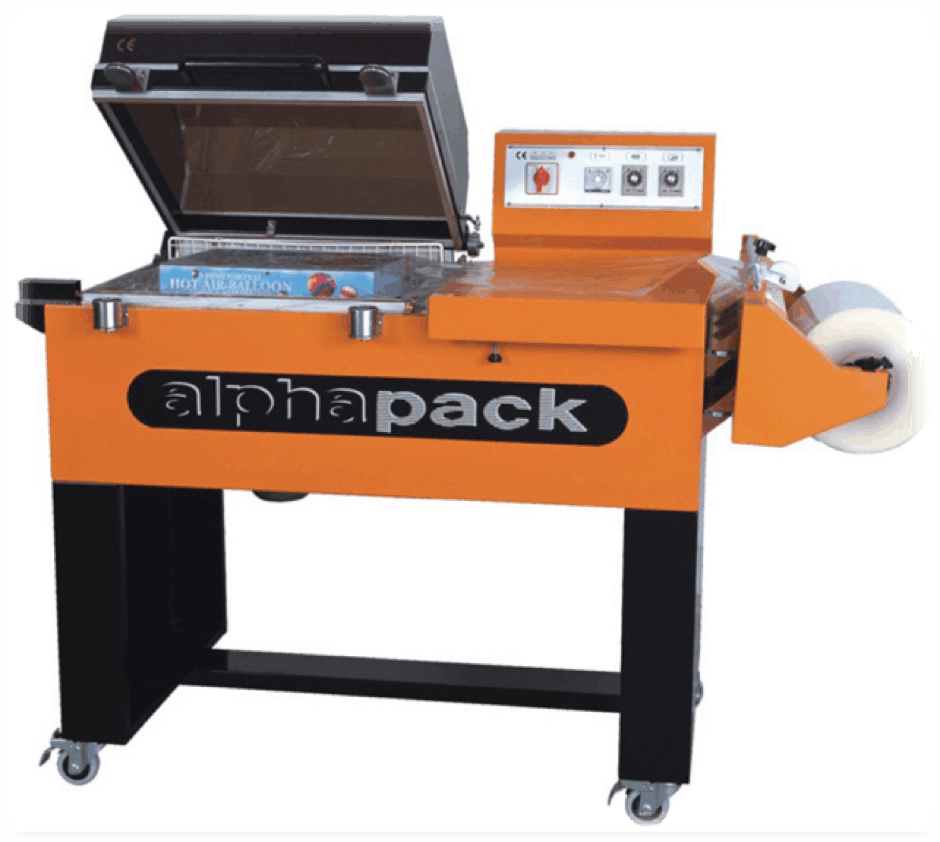

When a product is shrink wrapped, it is enclosed in a film; then heat is applied so that the film ‘shrinks’ and adheres to the shape of the product. During this process, air is significantly removed from the pack, but technically a true vacuum is not created.

What types of shrink film are there?

The types of shrink film that can be used are polythene, polyolefin and PVC, with each being used depending on the application and purpose, which we have looked at in more detail below:

Polyethylene (PE), or polythene shrink film as it is most commonly referred, is the most widespread shrink wrap film and is used in shrink wrap tunnels. Its principal use is as a transit medium which allows packs to be wrapped individually or collated, offering the best combination of protection and unit cost when compared to alternatives.

Polyethylene shrink wrap film is used on a vast range of products, from the individual wrapping of products such as pizzas, the collation of jars and can and even items such as radiators.

Polyolefin shrink wrap plastics (PO) have multiple layers of PE and polypropylene (PP). They can be irradiated for extra strength, and treated for hot slip or anti-fog properties. Polyolefin shrink wrap packaging offer a wide sealing and shrinking window so that they can be readily used in manual, semi and fully automatic shrink wrapping machinery. They are also extremely versatile so are often the first choice when using display shrink films; PO shrink plastic will offer an excellent solution to a shrink film requirement.

PVC shrink wrap plastic films have been largely superseded by polyolefin shrink films. PVC films have particularly easy sealing and shrinking features, but they are inferior to polyolefin shrink films in the areas of strength, low-temperature flexibility and equipment maintenance requirement. They continue to be used on very flexible packs, particularly heat sensitive products and, generally, on older equipment.

What is vacuum packing?

Vacuum packing is a method of packaging that removes air from the package before sealing. This method involves placing items in a plastic film package – either manually or automatically – removing air from the inside, and sealing the package. Shrink film is sometimes used to have a tight fit to the contents, which is why many people often mistake the two processes.

What is vacuum packing used for?

Vacuum wrap is most often used for perishable products such as meat or vegetables as it removes oxygen from the package. This gives the product a longer shelf life as there is no oxygen for bacteria or fungi to breed and make the product spoil.

As well as being used to prevent fresh produce from spoiling it is also used to store dry foods for a long period, such as cereals, nuts, and even crisps. In the case of foods some easily perishable products, the vacuum process can also allow modified atmospheres to be introduced, to further extend shelf life, depending on the specific product type.

Many vacuum wrap products are easily available on the domestic market, such as vacuum bags for clothes where household vacuum cleaner can be used to create an air-tight package. This is especially useful for packing a suitcase as it reduces the weight of the package and gives you more space. Although special vacuum packaging machines do exist, they are largely used on an industrial scale for produce and products.

Updated for 2017