Updated for 2019

Modern packaging machines are an essential part of any business selling large amounts of goods. If you are interested in incorporating a shrink wrap machine into your business to improve the efficiency of your current packaging solution, read on below for information about exactly what a shrink wrapping machine is and how they work.

What is Shrink Wrapping?

Shrink wrapping is a procedure where an item is wrapped in a free sleeve or envelope of loose polyolefin shrink film, and heat shrinks the wrap and firmly around the product. The result is a tight, crystal clear wrap around your item.

Shrink wrapping is typically stronger than alternative wrapping solutions like overwraps or stretch wraps. They also conform more tightly to the product shape, usually simply producing a thin amount of plastic over the perimeter of your goods.

What is Shrink Wrapping Machinery?

Shrink wrapping can either be done by a heat gun or through dedicated shrink wrapping machinery. Heat gun shrink wrapping is most often done by individuals who have a very small number of products to shrink wrap each week. For businesses, a shrink wrap machine is vital to efficiently and quickly wrap as many products as they can in as short an amount of time as possible.

What kind of shrink wrapping machinery you need for your business will depend upon understanding your current wrapping process and what you want to achieve. You will need to think about the motivation behind the wrap, how quick is the generation procedure, what range of sizes are required and how fast a changeover is required. Whatever the need, there will be a shrink wrapping machine created to meet the application.

How Does Shrink Wrapping Work?

Many of us don’t really think about how a shrink wrap machine works or how the plastic ends up wrapped tightly around the product. However, it is about controlling and manipulating polymer particles; polymers are long atoms found in plastic, where they are generally twisted and arbitrary, and therefore unsuitable to act as a wrap. When they are made into a plastic film for shrink wrapping, the molecules are extended straight into a thin layer, perfect for wrapping around another product.

This film is then positioned around whatever needs to be wrapped. Once the warmth is connected to the film, it shrinks, because the heat makes the polymers come back to their regular tangled state. How much a polymer shrinks depends on what kind of polymer it is: PVC shrink wrap film can shrink as much as 50 percent of its unique size, while polyolefin shrink wrap film shrinks slightly less, despite offering stronger seals than PVC.

The Benefits of Shrink Wrapping

Shrink wrapping makes products more sealed and keeps out dampness and light introduction as well as protecting the product during transit. Shrink wrapping, for instance, is excellent for CDs as you can observe the cover, as well as food products and pharmaceuticals. Shrink wrap is also known for being a low-cost packaging solution, with an outlay for the packaging machine, polyolefin shrink wrap film is very economically friendly. Polyolefin shrink wrap film may seem thin – it is, in fact, the thinnest on the market – but this doesn’t compromise its strength.

Having been tried and tested for many years, these are just some of the reasons that shrink wrap is one of the leading packaging solutions in the world. For more information, read our article on the benefits of shrink wrap and how it can help your business.

How do Shrink Wrapping Machines Work?

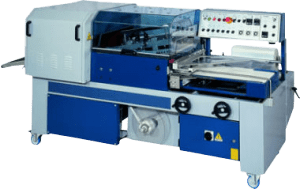

How a shrink wrapping machine operates depends on the type of shrink wrapping machine involved. The three significant kinds of shrink wrapping machines are the chamber sealer, the L-sealer, and a side sealer.

A chamber sealer puts the product with the shrink wrap film through a compartment, or chamber, where the shrink wrap is ready to be wrapped around the product. The compartment is heated, so the shrink wrap then compresses, surrounding the product and forming a protective layer. The time this process takes depends on the thickness of the plastic.

An L-Sealer is specifically designed for larger volumes of shrink wrapping. If you are using one of our automatic L-sealers, once plugged in and set up, you feed your product through the machine.

The L-sealer has two sealing bars, which make a backwards L (hence the name). The shrink film folds along these bars to create a pocket through the crease of the fold for your products to enter. Once your product is placed in that crease, the other three sides of the shrink film need to be sealed. The shrink wrapper detects when a product is entirely in the machine to know when to wrap your items with shrink film before pushing it further down the production line. Afterwards, typically a shrink tunnel in the production line takes the unheated shrink wrap that has been attached to each item and heats up the wrap until it tightly fits around each product.

Finally, a side sealer is the quickest and most versatile way of packaging large volumes of products. They wrap products in a continuous tube of film, sealing one side of the package then separating individual units downstream through a cross seal. Side sealers usually come in one of two configurations: two belts or three belts. A two belt sealer is more compact (only slightly bigger than an L-sealer) and eliminates one of the infeed belts to make the end seal before the side seal. They are best when you need to wrap longer products but cannot afford to expand production line lengths. Three belt sealers are slightly larger than two belt sealers and have the added advantage of precisely spacing the products before entering the wrapping area.

The Benefits of Shrink Wrap Machinery

If you decide to use shrink wrap in your business, there are many reasons to prefer using shrink wrapping machinery over alternative packaging methods. For one, automatic shrink wrapping machinery dramatically speeds up your production line. By substituting in manual wrapping for an automated machine, you do not need to complete the tedious, time-consuming tasks of packaging products in shrink film, which gives you more time to achieve more meaningful work. You also save on film costs: automatic shrink wrapping machinery is much more efficient with the amount of film it uses on each product than someone could hope to be by hand, which means shrink wrapping machinery can save you even more money in the long run.

Shrink wrapping machinery also helps significantly with inventory control. On the one hand, when you use the right shrink wrapping machine, your goods will be securely wrapped to prevent damage from dirt, dust, and moisture. This can give you added peace of mind that your stock is ready for shipping. On the other hand, shrink wrapping lets you bring consistency to how much shrink wrap you use per product, allowing you to more accurately know how much material you will need at any one time and reduce your storage requirements.

Here at Kempner, we have a range of shrink wrapping machines which can fulfil every shrink wrap requirement. What shrink wrap machine will most benefit your business depends on your needs. We have many years of experience working in this market and offer the most extensive and most comprehensive range of shrink wrap machinery and materials in the UK. Get in touch below or leave us a message and we will be happy to be of assistance.